EMI Test

EMI test, ESD test and the burn-in test are the three most important tests for computer systems. These tests help identify the systems stability and the protection ability towards the environment and the components inside. Among these three tests, EMI test is the one we should care about because it is highly related to human health and the working environment.

EMI test, as it means, is the test to identify the extent of the electromagnetic interference the system will generate. If the system generates too strong electromagnetic field, it will interfere the signal transmission of the machines around it and cause noise signal or even stop the signal. If the system is near the airport, broadcast tower, or the airpath, it will cause severe safety issues. It may damage other machines potentially if these machines use electromagnetic sensitive components.

The EMI not only affects the machines, but it may harm our body. According to the research, human will suffer from dizzy, headache, fatigue, memory reduction, insomnia, and anxiety if expose in the high electromagnetic field in a long time. It will also affect the immune system and the reproductive system. Therefore, there are several international standards to limit the EMI from the system, reducing the potential safety and health risks.

From our past experience, there're three key factors will affect the EMI: grounding, shielding and the filter.

Grounding is the basic of the basic to solve the EMI issues. From our experience, over 90% EMI issues can be solved by improving the grounding. However, it is not as easy as you may think.

In the computer system, normally we use the chassis as the ground for the internal components because the computer case is made of metal which is conductive and low impedance in general. In the meanwhile, the case has enough coverage area to help absorb the electrical wave and reduce the noise. Therefore, it is an ideal ground for the internal device. Whereas, the grounding point is important. It must be clean and highly conductive. If the grounding point is covered by the paint, the conductivity will be low and the ground effect will be reduced. That's why systems meet the EMI standard always use chassis with half coating.

When improving the grounding during the test, we first need to find the source of the EMI. We'll need to test each component by connecting or disconnecting them. At the same time, we'll need to observe the change of the EMI test result so we can find the root cause. In lucky case, the device emits the EMI noise just because it fails to connect well to the ground. The EMI issue can be solved when we improve the connectivity by scratching the paint or brush the oxidized surface on the grounding contact or just connecting the ground wire well. But in most cases, it is more complicate when the EMI is generated because the bad design. When it happens, we can only try to add ground point for the device. If it still not works, we'll have to change the device and ask the device provider to improve it.

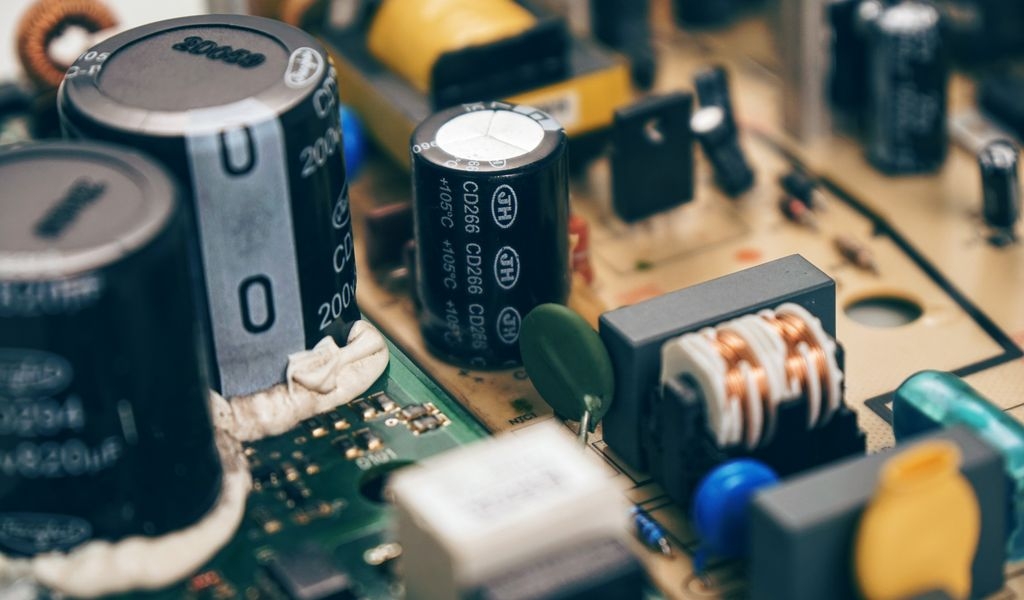

Though grounding improvement can solve most problems, shielding can help the result to be better. The shield is normally a metal shell and can prevent the electromagnetic noise leaking from the source. The computer case itself can be seen as an effective shield. However, as the case has to open some holes to help cool the device inside, the shielding effect is normally not as perfect as expect. Choosing shielding cables, designing the shield layer directly on the PCB board or adding it when packaging the chips are common ways to build the shield.

The last solution is adding the filter. The filter can be internal or external. The internal filters are normally included in the circuits when designing the device. It is the most effective way to reduce the EMI generated from the device. However, sometimes it is missing due to the cost control policy. When facing this situation, external filter is the only solution. The common external filter is the ferrite bead. It is a small, circular device. It can be either built with the cables or become an independent detachable device. The ferrite bead itself is magnetically and will generate magnetic field to mitigate the high frequency signal when the current pass nearby. To use the ferrite bead, be sure to find suitable size and circle the cables through its center. After lock and fix it on the cable, the bead will function well. You may need to try different bead to reduce the EMI successfully because there are different beads with different inductance value. Only the compatible one can solve the EMI issue effectively.

To pass the test successfully, Yeong Yang did lots of efforts and we're experienced to help our clients solving the EMI issues. Furthermore, we included the EMI shielding solution when developing the products. Most our PC casing products are half coated and have good grounding contact design for the components. It will have less works and worries when using our products to pass the certification. As we promised, we always provide the best products to our clients. Feel free to contact us if you have any thought.