Burn in Test

Being a system integrator, after you successfully purchased every item your clients need and build them up into a system, how do you make sure the machine you provide is OK? Yes, the answer is the burn-in test. It is the process which may not be important for end users but is important for system integrators. Every system integrator should run before shipping the products.

The burn-in test is important because it has the following benefits.

First, it can help found the hardware compatibility issue which is not detectable at the early stage. Though most PC components are standardized, somehow there still are some issues like the header mismatch problem, signal mismatch problem or the power deficiency issue.

The header mismatch problem is often caused when users plug at the wrong position or plug the wrong header. It may sound ridiculous. Whereas, there does exist some similar header spec which can be easily plug wrong, like the pitch 0.8mm pin header and the pin 1.0mm pin header. User may force them combined if they fail to recognize the difference. The pins may be damaged or become unstable.

The wrong header position problem is a common happened problem because some users don’t read the manual or the spec file carefully or even neglect it when assembling the machine. It will cause the hardware either recognize the wrong signals or send the wrong signals to the incorrect pins. The wrong position issue often be found when the errors accumulate to an extent.

The power deficiency issue happens when users calculate the wrong power consumption value or forget to estimate the buffer value. Though now it is convenient to calculate the power consumption of the system using the online tools, user often to forget to include the influence of the peak power consumption value and buy a smaller power supply. The insufficient power supply will cause the system run in unstable state and cause hardware damage in the worst case. Normally, we suggest adding 20% of your total power consumption to avoid this issue. The long-time burning test can help detect these issues.

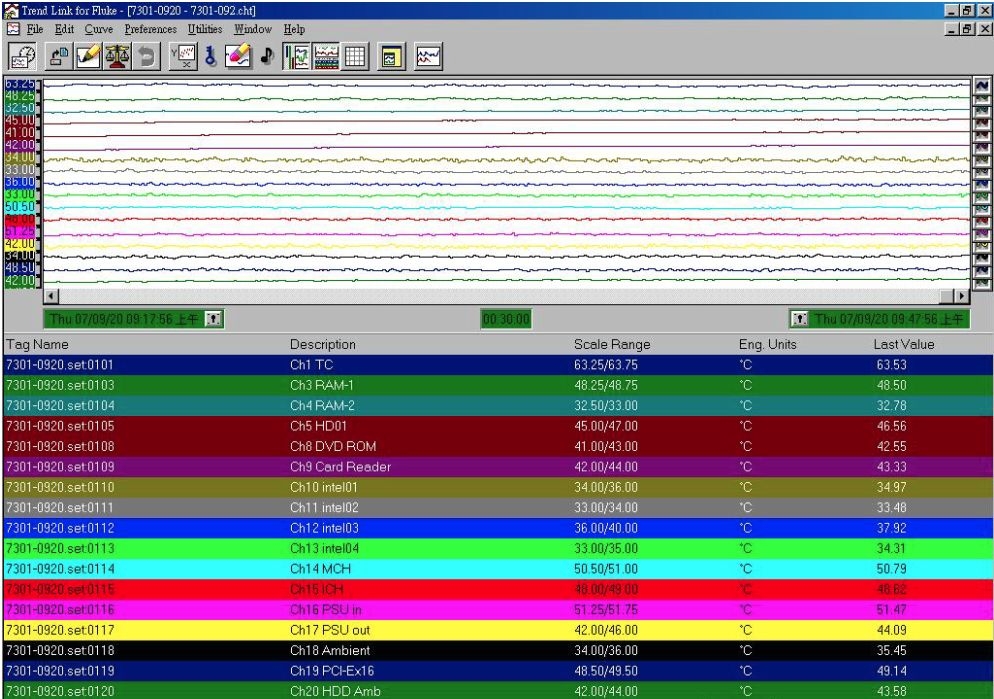

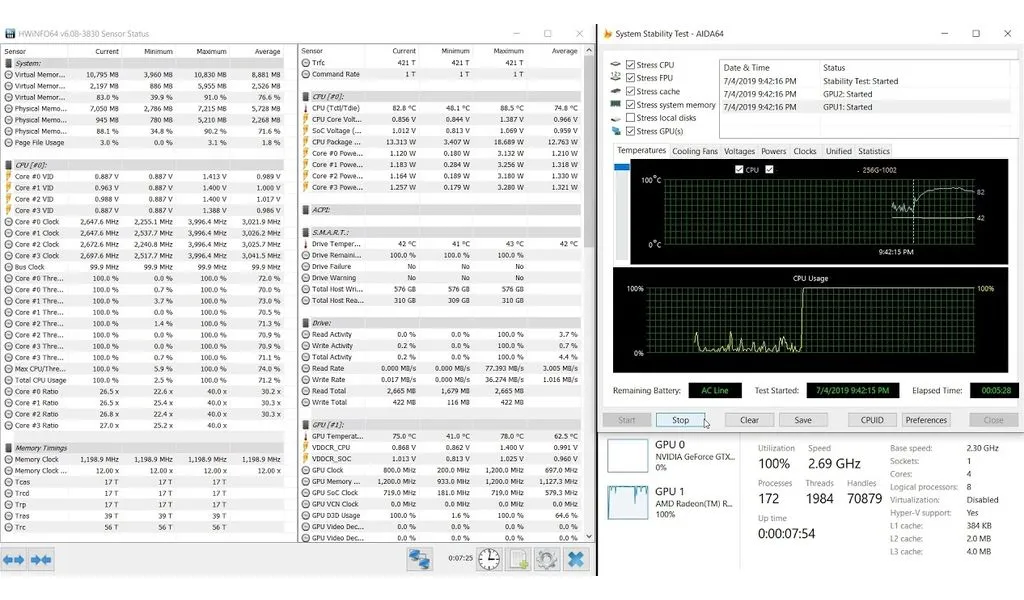

Secondly, it helps filter the defect devices. In room temperature, most device would run without problems, even the device with inferior quality. Whereas, when running the machine in a harsher environment, things can go totally different. For example, in a high temperature environment, cooling issue will happen if the thermal paste is not enough or not spread evenly on the interface. Some production issue will also be exposed if low quality components, such as the capacity or the resistors, were not examined and were used during the process. Some joint parts using glues to combine each other may also detach when the glue lose its function in the high temperature environment. The burn-in test can help create the environment in real working temperature to help filter these issues.

Last, the potential driver issues can be detected during the test. Some configuration errors or signal errors only reveal under some specific circumstances or after accumulating for a long time. One common issue is the mismatch of the operation system and the hardware drivers. People sometimes use former drivers for the new OS system. It might work at the early version of the new operation system, especially when the system just rollout the upgrade version. However, most of the time the new system contains new functions or has some changes on its architecture that old drivers don’t supports. It only tolerates the old drivers for a short time to help users to overcome the period when the manufacturers are still developing new drivers. When the period ends and the operation system becomes stable, continuing using the old driver will cause the system to be unstable. Take the GPU cards as an example. If the system integrator installs the unmatched drivers, users may encounter blue screen or glittering issue after using a while. Running the burn-in test

However, the burn-in test requires time and suitable software or equipment to perform correctly. It means you need to invest to build the test machine or buy authorized software to get the correct test configuration and the result. Also, you may need to find a crew to help you monitor the test in case there’s any accident. Several times burn-in test may be required too to ensure the machine is tweaked to the best state. Though it sounds frightening, it is still a worthy investment comparing to the potential RMA issue and complains result from unusable or bad quality products.

The burn-in test is an effective process which can help the system builders filter the potential system failure factors and provide the chance to improve and repair the issue before shipping to clients. Though it might delay the whole production process and produce additional cost to maintain and perform, it is a required process for every system integrator. Yeong Yang technology cultivate in the PC and server chassis area for over 30 years. We are familiar with the mechanical issues and the cooling issues which often be discovered during the burn-in test. We can help our clients solve the issues quickly and efficiently. What’s more, we can help our clients tweak the product in the early stage to avoid the issues. Welcome to discuss with us if you encounter any problem. We wish we’ll have chance to work with you.